Re-gearing: The Whens, Whys, Wheres and Hows and Everything in Between

I'm sure you've heard fellow Jeepers and wheelers alike discussing gear ratios or gearing in general at some point in the past. There is a lot of useful information you should know of and consider when it comes to whether or not re-gearing is truly in the cards for your Jeep, truck or 4x4 vehicle. What do gears do? Why should I re-gear? When is the ideal time to re-gear? Where should I bring my vehicle for this service? And so on and so forth. Bear with me while I break it down.

What are the gears?

Your drivetrain is originally geared to provide your vehicle with proper balance and torque. Once you bump up in tire size, this throws your drivetrain, speedometer, shift points and performance out of whack. The factory gears are decided based on the year of your vehicle and the package it comes with. Common packages are 3.21's and 3.73's. Gearing of the axle is regulated by the amount of teeth in your ring and pinion gears. This number in turn determines how many rotations your driveshaft has to make to spin your wheel once. Example- with 3.21 gears, your driveshaft would have to rotate approximately 3 1/4 times for your wheel to complete one revolution. With 4.10 gears, the driveshaft would have to rotate approximately 4 times for your wheel to complete one revolution.

What exactly do the gears do?

Your vehicles driveshafts, front and rear, connect to the axle shafts on the pinion gears. When your driveshaft rotates, the pinion gear spins the ring gears which, in turn, spin your axle shafts, making your vehicle move. Once larger tires are added to the equation, your fuel economy, power and performance are compromised. I don't know about you, but I enjoy driving my lifted JK on the highway and still being able to keep up with the flow of traffic without my wallet or gas tank suffering.

**Photo Credit: Justin's Auto and Off Road in Norton, Ma

How will my vehicle benefit from new gears?

Re-gearing can and will improve your vehicles top speed, fuel efficiency and performance. Off-roading and upgrading to larger tires changes to overall diameter of the tire, roll resistance, tire rotation and adds weight of the tires into the mix. Your tires diameter governs how hard your drivetrain needs to work in order to make your vehicle move. Your driveshafts will turn slower while driving down the road, compromising your power and performance. The harder your drivetrain needs to work, the slower your vehicle will move. Jeeps, trucks and 4x4 vehicles weren't designed to be Lamborghini-fast but they also weren't made to be slug-slow either. Without gears, you are increasing the amount of force sent to the axles, which can cause a lot of breakage. Re-gearing to the proper ratio will allow your vehicle to move and function with less stress to the axles. Upgrading your gears ultimately gets your vehicles engine and drivetrain capabilities back to factory-like performance.

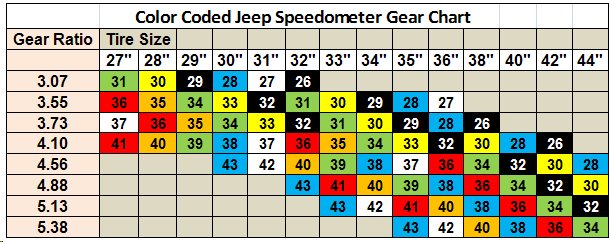

Ok! I'm ready for new gears! But which ones are the right ones for me?

There are two types of gears out there for you to choose from; low numbered and high numbered. Low numbered gears, often called "taller gears" tend to be faster at highway speeds before reaching the redline. These gears, in the off road world, are referred by those who gravitate more toward mudding, since you need the speed to keep your vehicle moving and tires spinning and biting. High numbered gears, also known as "shorter gears" will redline quicker and at lower speeds. These gears are ideal for those who tend to rock crawl. Shorter gears allow you to go much slower over rocks and other obstacles giving you, the driver, more control and making it easier on your suspension, armor and driveline components. This also allows you to methodically calculate your line, rather than having to hammer down to get over the obstacles.

What should I know before I re-gear?

When planning to re-gear in any 4x4 vehicle, money, attention to detail and time need to be premeditated. Re-gearing properly and professionally is not an instantaneous upgrade. Allow yourself a day or two to have your Jeep in the shop. Do your research on shops beforehand as well, making sure the one you choose is reputable and with staff that is knowledgable about your vehicle, gears and the re-gearing process. Gearing is a labor-intensive job so make sure along with purchasing the gears, you have money aside to cover the labor costs. "Good work ain't cheap and cheap work ain't good." The time spent re-gearing, to put it lightly, is a lot of work and needs to be done correctly, saving you from breakages and more damage in the future, so this job should be left to the professionals. When you re-gear, both the front and rear axles need to be done at the same time. Why, you ask? Your transfer case is designed to work in conjunction with your front and rear driveshafts and they should be spinning at the same speed. Any significant difference in driveshaft rotations can result in a t-case breaking.

I don't know what gears I'm currently running. Is there a way to find out?

If you're unsure of what gear ratio you are currently running in your vehicle (bought it from a used car dealership, private party sale, can't find the paperwork, etc) there are a few directions you can go with, both without having to remove the differential cover. The first, and less time consuming, option would be to call your local Chrysler Jeep Dodge Ram dealership, ask for the service center and provide them with your VIN number. If this isn't possible, grab a buddy and a few jack stands. Jack the rear axle up, support it with the jack stands and put the transmission in neutral. While one person rotates the rear driveshaft by hand, keeping a close eye on the number of rotations, the second person watches for the wheel to make one full revolution. Refer to the chart below for a general reference:

# of Driveshaft Rotations Approximate Gear Ratio

3.25 3.21:1

3.5 3.55:1

3.75 3:73:1

4 4.10:1

4.5 4.56:1

4.75 4.88:1

So why should I believe you?

We're no re-gear specialists by any means, nor do we claim to be but obviously we wouldn't provide you with this information unless we had our Jeeps re-geared as well. Shanaynay, our 2008 Jeep Wrangler JKU Sahara with 150,000+ miles has been running the Motive Gear Complete Re-gear Package with Master Install Kit and 4.88 gears for a few years now with no issues. Frankie Van Halen, our 2015 Jeep Wrangler JK Sport with 28,000 miles has been running the same kit but with 4.56 gears since the spring of 2016 and we have nothing to complain about. You can view all of our gearing options here.

What should I do after re-gearing?

Most installers will warn you not to do any wheeling for the first 500 miles or so, so it's best to plan your install when you know there aren't any off-roading trips coming up. Some people wait for the off-seasons to do theirs, others aren't their daily driver so they can be done whenever. It really is completely up to you on when you want to get them done. The reason to wait until the 500 mile mark is to ensure the gears are working properly, to check and change the fluids and to make adjustments if adjustments are necessary. We recommend purchasing a tuner or programmer if you haven't already. A tuner will recalibrate your speedometer tire size and shift points. Tuners and programmers cannot be shared between vehicles since they tap into your internal computer so don't go borrowing your buddy's....that's not how it works. Our 2008 is using the Superchips Flashpaq programmer and our 2015 is using the Superchips FlashCal programmer. You can view our entire inventory of tuners and programmers here.

So there you have it! The ins, outs, ups and downs of gears and re-gearing. Hopefully I made your decision a little easier to make and of course, if you have any questions, feel free to drop us a line! Get out there, get geared and hit the trails with confidence!

PRODUCTS MENTIONED