Our M416 Military Trailer Project

Posted by Eric M. on 30th Jan 2016

As many of you may know, we attend and vend many of the offroading events in New England each year. For the first few years, we relied solely on friends with Jeeps to help relocate almost our entire shop and inventory to each event. This took trust, dedication and reliability. One of our friends and fans happened to have a military trailer that we loaded time and time again and we admired the capabilities of this trailer. That's when we started our search for our own trailer.

Our M416 Military Trailer was one of our favorite short term projects which has now become more of a long term project. A couple hard working weeks, late nights, and some bloodshed of the knuckles made it well worth it! Mid June 2015, after searching for months, we finally found our M416 Trailer in great shape on Craigslist, no rot and some pretty straight body panels.

We drove to Rhode Island and picked it up - it was well worth the $1,000 they were asking.

The master plan was to follow the footsteps of my buddy Matt, who had done up his M416 to match his Jeep, Shrekicon. Spring over lift, matching wheels/tires, and paint to match the Jeep.

From there we went into design mode...wanting the trailer to compliment our 2008 Jeep Wrangler Unlimited Sahara. So the project begins.

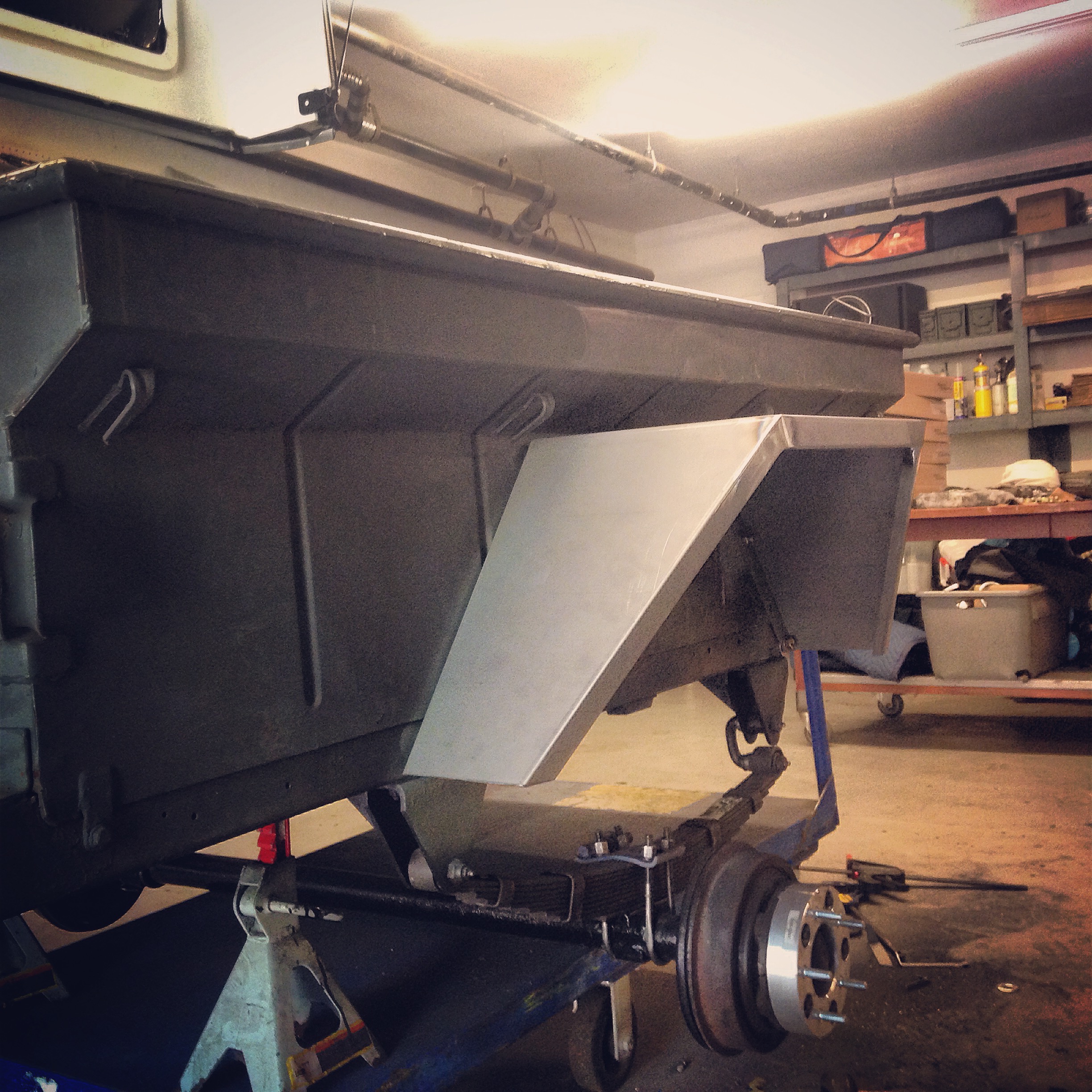

We pulled the axle, brake lines, and leaf springs out, then wire-wheeled the underside to get rid of the small layer of rust that had accumulated over time. Using Rustoleum Undercoating on the belly and semi gloss on the axle.

Once completed, it was time to do the spring over lift. We traveled to a local autobody shop for some new leaf springs and u-bolts. The same day, we put a new pair of 37" Nitto Mud Grapplers and 17" Method Race Wheels on order to match the Jeep.

In the re-assembly process, we realized some customer fenders would be needed to clear the 37s, and it would look pretty cool too! Keeping most of the original specs and dimensions in mind, the cardboard fabrication started.

Templates and dimensions were then brought to a local fabrication shop to be cut, bent, and welded.

Fenders bolted up and final trimmed. 5on5.5 to 5on5 wheel adapters were used to keep the same JK bolt pattern - this way we had all the same wheels to keep everything consistent.

Clearances looked great. Now time to swap out the old ball hitch with a Lock N' Roll hitch system.

Now to paint and some articulation testing!

Whether it be events, offroading, or leisure - we built a fun one of a kind piece and enjoy every minute of using it!

Keep on Jeepin' on and remember, there are endless possibilities when it comes to a Jeep!